Aqueous Coating: The Unsung Hero That Makes Your Prints Look (and Feel) Expensive

Excellent printing involves more than just bright colors and intriguing illustrations. It has to do with how your print looks, feels, and endures in the actual world. Aqueous coating acts as a stealthy Ace in this situation. It is one of the most popular print coatings, and for good reason: it's clean, quickly dries, environmentally friendly, and amazingly versatile.

The definition, types, contrasts, papers, business cards, paper cups, and even aqueous coating tablets (yeah, that's an actual thing) are all explained in this blog. This is perhaps the most open and practical guide you will ever read about aqueous coating.

Aqueous Coating Meaning (In Plain English)

The meaning of the aqueous coating is quite obvious. It is a water-based protective coating that is put on printed paper following the application of ink. Aqueous coating is cleaner for humans, better for printing presses, and safer for the environment than solvent-based finishes because it doesn't contain any harmful, toxic substances.

Imagine it as a transparent shield that:

- Prevents dirt, fingerprints, and smudges.

- Amplifies the intensity of each hue.

- Increases durability.

- Adds a particular texture and appearance (matte, satin, glossy, or soft-touch).

If you've ever wondered what an aqueous coating is, it basically explains why your retail or gift packaging doesn't appear worn out after use.

Furthermore, aqueous coating and aqueous varnish coating are frequently used interchangeably. The point of difference? Generally speaking, varnish is thinner. On the one hand, coating provides more consistent preservation and coverage. On the other hand, AQ often provides extraordinary uniformity for quality prints and packaging.

Why Brands Love Aqueous Coating (And You Should Too)

- Recyclable and environmentally friendly.

- Faster drying.

- Adaptable to different kinds of paper.

- Cost-conscious without looking shabby.

- The ideal ratio of finish to barrier protection.

It’s not loud! It’s not flashy! But it works! And works beautifully!

Aqueous Coating Machine: How It’s Applied

Using quality rollers or controlled spray systems, an aqueous coating machine delivers a water-based layer of protection to printed paper, guaranteeing that the finish covers the surface evenly and without smears or pooling. Commercial and packaging printers choose this mechanical method because it has been optimized for pace, consistency, and productivity.

Usually, inline aqueous coating systems are built right into the printing press. Because printing and coating take place in a single pass, cutting time and minimizing handling, these are perfect for high-volume, bulk packing tasks. In contrast, sheets are coated after printing by offline machines. They are suited for short batches, specialist projects, and settings requiring precise control over coating weight and finish.

Here’s what the machine delivers:

Even distribution: The sheet is evenly covered from edge to edge by rollers that measure the coating at a predetermined thickness. This avoids dull areas or uneven polish.

Quick drying: By rapidly evaporating water, hot-air or infrared dryers enable sheets to be processed, stacked, or completed in almost no time.

Consistent finish: Whether gloss, satin, or matte, the outcome remains consistent throughout extended print runs, which is necessary for maintaining brand coherence.

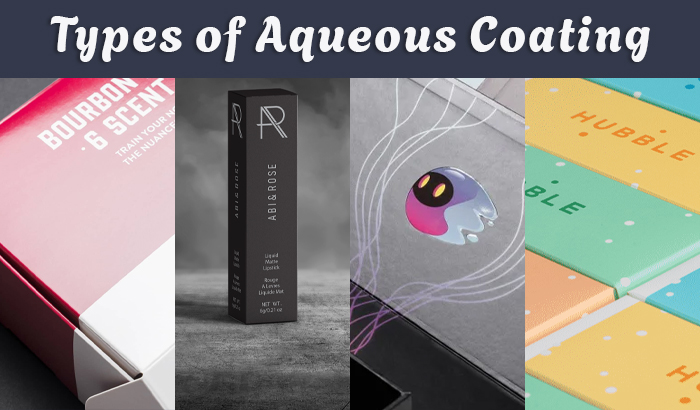

Types of Aqueous Coating (Choose Your Vibe)

Gloss Aqueous Coating

Gloss aqueous coating deepens blacks and intensifies colors. No doubt, it maintains professionalism while enhancing contrast. This type is great for:

- Retail packaging, because it adds gloss without appearing plasticky.

- Flyers for promotions

- Product labels

Matte Aqueous Coating

Matte aqueous coating would be the look and feel of grace. Smooth refinement without any glare, smears, or fingerprints! Consider it ideal for:

- High-end custom display boxes

- Simple branding

- Expensive promotional items

Satin Aqueous Coating

Not very glossy. Not very flat. In the middle is where the satin aqueous coating exists. The "naturally cool" finish has proven successful in a variety of industries.

Soft Touch Aqueous Coating

This is a crowd-pleaser! The velvety, rubbery feel of the soft-touch aqueous finish emanates beauty.

Typical applications include:

- Rigid boxes

- Pretty sleeves

- Forward-thinking, branded packaging.

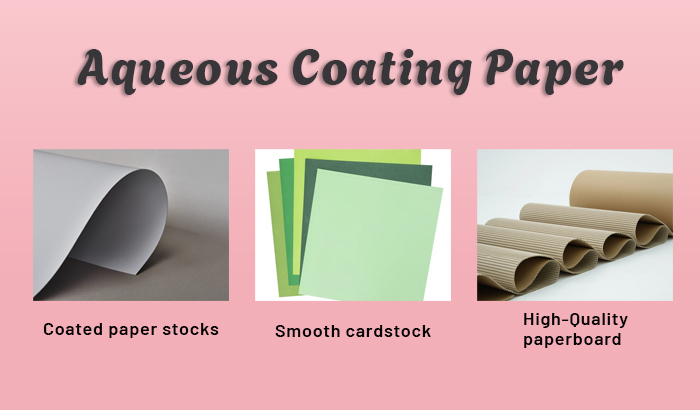

Aqueous Coating Paper: What Works Best?

Because not all papers are found compatible with aqueous coating, careful material selection is paramount. Choose the paper stocks that let the coating sit on the surface rather than soak into it because it is water-based.

Porous or uncoated papers, such as textured stocks or raw kraft, have a tendency to absorb excessive amounts of the coating. This can lessen color saturation, mar the finish, and minimize the coating's protective qualities. Generally speaking, aqueous-coated paper works flawlessly on:

Coated paper stocks

Because gloss or matte-coated papers offer a sealed surface, the aqueous layer can spread uniformly. The outcome? improved print clarity, brighter colors, and an uninterrupted shine.

Smooth cardstock

Smooth, dense cardboard allows for consistent coating application without blotting. When durability and aesthetic gloss are required, it's perfect for packaging, covers, and marketing materials.

High-quality paperboard

For retail cardboard boxes, folding cartons, and personalized packaging that demands both strength and style, premium paperboard is suitable. It adds rigidity and safety while holding the coating well.

What Is Aqueous Coating in Printing?

In printing, aqueous coating is done either offline (after printing) or inline (during printing). It dries quickly, adheres to ink effortlessly, and doesn't yellow or flake over time. In contrast to UV coatings, which necessitate heat and specific curing methods, aqueous coatings dry through absorption and air.

Most importantly, it works brilliantly with digital and offset printing. When used properly, it is safe for food-grade packaging. Because of this, it's a preferred option for anything from high-end boxes to regular marketing materials.

Aqueous Coating in Digital Printing

Yes, aqueous coating digital printing is absolutely a thing, and a growing one. With modern presses:

- Ink adherence gets improved by coating.

- Guards against scuffing during handling

- Supports variable and short-run printing jobs.

Because it's quick, adaptable, and affordable, digital brands adore it.

Aqueous Coating vs Other Print Finishes (Let’s Compare)

Here’s where things get interesting.

| Feature | Aqueous Coating | UV Coating |

Lamination |

| Finish Look & Feel | Soft sheen or matte; charming yet realistic without being overly glossy | High-gloss or matte with a stunning shine | Smooth, plastic-like surface; can be glossy, matte, or soft-touch |

| Thickness | A light, thin coating that preserves the natural texture of the material. | Rests on the surface of the paper and is thicker + more solid. | The thickest option covers the paper with a discernible coating. |

| Flexibility | Extremely pliable; won't break in creases or folds | Less pliable; could break when folded | Restricted adaptability; folds need to be scored |

| Durability | Strong defense against mild moisture, streaks, and scuffs |

Outstanding resilience to nicks and scrapes |

Strong protection against moisture and wear |

| Drying Time | Fast air-drying | UV light cures instantly | Needs force or heat to form a bond. |

| Eco-Friendliness | Water-based, recyclable, and ecologically conscious | Less recyclable due to chemical curing | Plastic layers make it the least environmentally friendly. |

| Recyclability | Fully recyclable with paper | Limited recyclability | Difficult to recycle |

| Cost | Scalable and affordable for large-scale operations | Prices are higher because of the curing procedure | Depending on the type of film, moderate to expensive |

| Best Use Cases | For retail displays, folding cartons, subscription mailers, and branded boxes | Top-class marketing prints, spot effects, and luxurious packaging | Premium packaging, menus, covers for books, etc. |

| Overall Vibe | Clean, upscale, and regulated like mood lighting | Dramatic + striking, akin to a spotlight | Rich + polished, but heavy |

Aqueous Coating Calculator: How Costs Are Estimated

In order to provide you with a reasonable per-unit coating cost, an aqueous coating calculator considers a number of production variables. What is included in the computation is as follows:

Sheet Size:

Bigger sheets use more material since they need more coating solution. However, the cost per piece can be reduced with effective imposition.

Coverage Area:

Spot treatments are less expensive than full-coverage coatings. The calculator determines the real surface area that calls for coating.

Coating Type:

Depending on formulation and efficiency, gloss, matte, satin, and soft-touch aqueous coatings have varying price points.

Print Run Volume:

Aqueous coating is particularly pocket-friendly for large-scale packaging runs because larger quantities significantly lower the cost per unit.

Production Speed:

Because aqueous coatings dry quickly, press speeds can be increased and labor time can be decreased, which results in indirect cost savings.

Material Absorption:

The amount of coating absorbed depends on the porosity and paper material, which can slightly alter the price.

Aqueous Coating Tablets (Yes, Really)

In pharmaceutical, nutraceutical, and industrial contexts, where accuracy and uniformity are more priorities over beauty, aqueous coating tablets are extensively utilized. When combined with water, these pre-measured, water-soluble tablets disintegrate into a homogenous coating solution.

The outcome? A regulated, reproducible coating procedure with less waste and no guesswork. Without using harsh solvents, aqueous coating tablets in pharmaceutical applications assist in protecting against active chemicals, increase tablet durability, control drug release, and help with swallowability.

They have been used in industrial settings to produce thin protective coatings that are safe, flexible, and resistant to moisture, scratching, and environmental exposure. Process efficiency is the largest benefit! Tablets improve worker safety, lower handling errors, remove solvent odors, and help water-based systems comply with regulations.

Aqueous Coating Paper Cups & Food Packaging

Aqueous coating is the preferred finish for food-safe packaging, particularly paper cups, takeout containers, and rapid-service meal boxes, because it is water-based, odor-free, and safe to use. It provides a barrier of defense without affecting food quality, taste, or smell. Exactly what food and beverage companies require!

| Benefit | How Aqueous Coating Helps Paper Cups & Food Packaging |

| Moisture Resistance | Keep your cups holding hot or cold liquids from softening, bending, or leaking. |

| Grease Protection | Packaging stays stain-free and clean by acting as a barrier against oils and fats. |

| Improved Durability | Reduces splitting, ripping, and wear during handling by strengthening the paper's surface. |

| Heat Tolerance | Performs well with hot drinks like coffee and tea without releasing odors |

| Print Protection | Prevents smudging and color fading even in humid environments by locking in ink |

| Eco-Friendly Appeal | Maintains recyclability and promotes sustainability objectives in contrast to coatings made of plastic. |

Aqueous coating guarantees that drinks are wrapped up, hands stay dry, and branding looks crisp, colorful, and professional - from the first sip to the last drop.

Aqueous Coating Business Cards: Worth It?

Absolutely, and here's why...

Aqueous coating business cards put in a lot of effort behind the scenes, in addition to having a nice appearance. When someone picks it up, the water-based coating produces a satiny, exquisite surface that seems high-end. No cheap gloss glare or waxy plastic sensation! Additionally, it adds a layer of protection that keeps your information visible and clear by preventing fingerprints, flecks, and moisture. Yes, it keeps text clear and polished while enhancing color vitality.

Cards are perfect for wallets, pockets, and regular networking because of their thin, flexible coating, which prevents them from readily cracking, curling, or scuffing. Aqueous coating is the wise, fashionable option if you want a spotless, self-assured first impression that lasts, and you don't want to go over budget.

Final Thoughts: Is Aqueous Coating Right for Your Project?

Aqueous coating meets all of your needs for sustainability, improved color, tactile interest, and clean protection. It easily adjusts to the personality of your company, whether you're printing paper cups, company cards, packaging, or promotional materials.

We Print Your Box is your expert here in packaging! Our professionals assist you in selecting the ideal option in addition to applying finishes and coatings. Call us: 888-385-1812, email us: sales@weprintyourbox.com, or hit us on live chat, whether you need 100 boxes or 100,000.

Recent Posts:

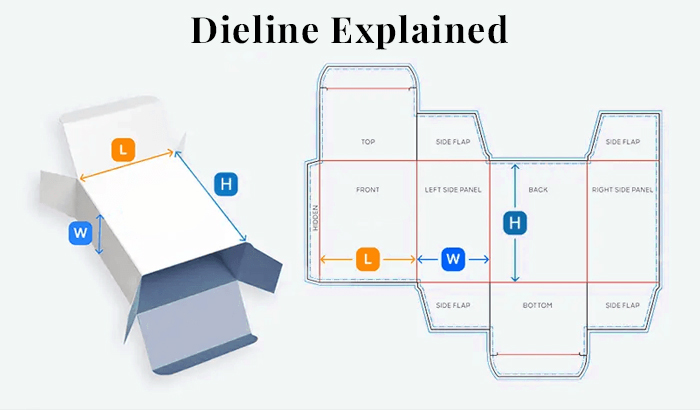

Dieline Explained: The Backbone of Smart Packaging Design

If packaging were a building, the dieline would be its blueprint. Dielines are invisible to custo...

13 Foil Stamping Colour Trends: Gold, Silver, Holographic & More

Packaging is now more than simply a cover for your goods; it's the world's first glimpse of your bra...

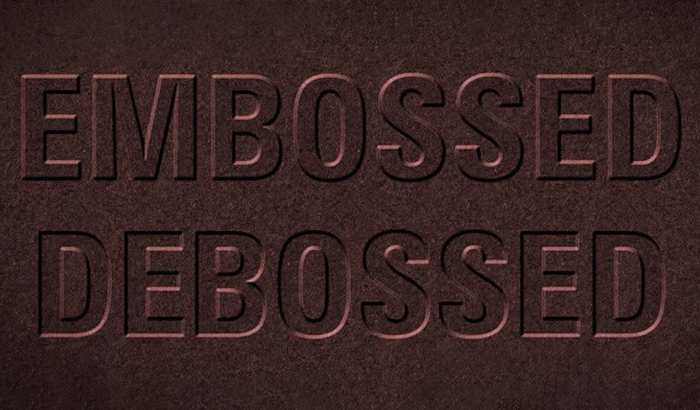

Embossing VS Debossing: Make Your Packaging POP!

The nuances are crucial when it comes to personalized packaging. While intriguing fonts and colorful...