Dieline Explained: The Backbone of Smart Packaging Design

If packaging were a building, the dieline would be its blueprint.

Dielines are invisible to customers but fundamental for all they see, feel, and experience. They silently influence how packaging appears, folds, binds, protects, and functions.

Understanding dielines can help you save time, resources, and frustration when launching new goods, updating the look of your company, or scaling up production.

Let's break it down plainly, cleverly, and without design school jargon.

What Is a Dieline? (And Why It’s Non-Negotiable)

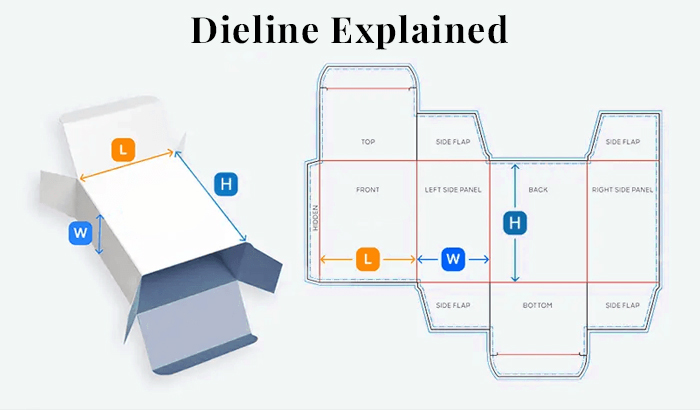

A dieline is an engineering model that illustrates the exact way a package will be shaped, cut, creased, glued, and assembled during manufacturing. It's the master concept that printers, manufacturers, and designers use to transform surfaces into complete boxes. Consider it the meeting place between art and technology!

Even the most beautiful artwork will not work if it is not properly dieline. Your output will have uneven folds, ripped logos, or boxes that won't close.

Dielines are used in nearly all packaging types. It adjusts to the particular requirements of each category (such as weight holding, sealing, and shelf presentation).

Cut/Fold Lines: The Language of Dielines

If dielines could speak, they’d do it through “cut and fold lines.”

Here’s how they work:

- Where the material will be cut is shown by solid lines.

- Folds are indicated by dashed or dotted lines.

- Scored lines guarantee smooth, crack-free bends.

Die-cutting machinery is guided by these lines with millimeter accuracy. Here, a small error can result in structures that crumble under pressure, have crooked sides, or lack stable and strong angles. Professional dielines are therefore designed rather than guessed.

Printing & Production

After your dieline is complete, printing and production are the next steps, and this is where perfection and carefulness really count. They are used by printers to:

- Align the printing plates

- Assemble die-cutting tools.

- Make sure the folding and gluing are perfect

- Cut down on material waste

Faster turnaround with fewer reprints and more affordable manufacturing costs result from a proper, well-prepared dieline that eliminates errors and speeds up the production process.

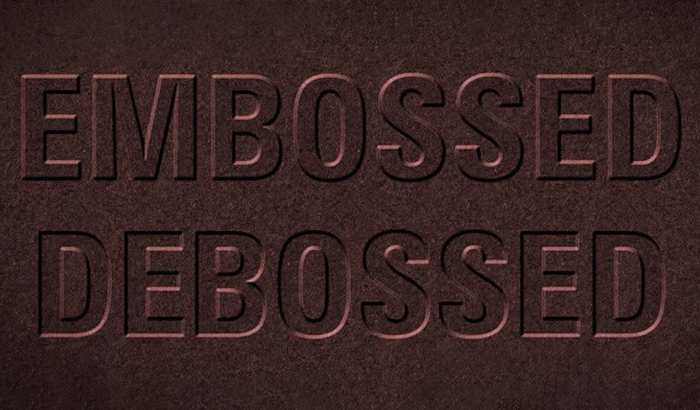

How Dielines Affect Finishes

- Tight clearance around folds is necessary for foil stamping.

- Structural support is required for embossing and debossing.

- Spot UV needs to stay away from seams and adhesives.

- Cutouts and windows need to have comparable finishes.

Glue Areas: Small Zones, Big Responsibility

Although glue regions may not look like much at first, they are actually what keep the whole thing together and guarantee that the box functions exactly as intended from assembly to ultimate use.

Glue regions are accurately specified in a professionally made dieline to show where glue should be placed, how much surface overlay is needed for a strong bond, and how many panels need to stay glue-free. Whether you're manufacturing a large-scale order or just a few custom runs, this clarity assures uniformity across every piece and avoids confusion throughout production.

Improperly planned glue zones can have quick and expensive repercussions. Printed artwork or specialized finishes could be harmed by adhesive seeping into visible places. Poor or weak glue contact can lead to uneven walls, loose openings, or boxes that give way under light pressure. Excess adhesive can occasionally obstruct folding lines, making assembly challenging and uneven.

Because of this, logical dielines try to keep glue regions away from important design components. This drawing preserves the packaging's toughness while safeguarding its aesthetic integrity by separating these areas. The end product is a box that is tidy, sturdy, and durable, demonstrating that even the tiniest details are significant in excellent packaging design.

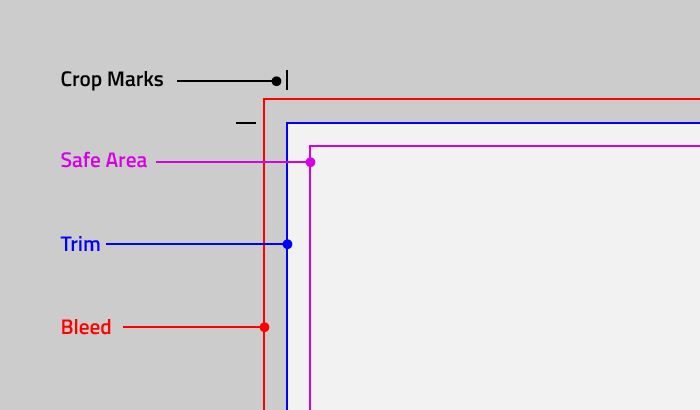

Bleed, Trim & Safety Zones: Printing’s Safety Net

It is a beginner error to ignore bleed and trim requirements, which are always included in specialized dielines. For aggressive designs, dark textures, and edge-to-edge coloration, this is particularly important.

- Bleed prevents white borders by extending artwork past cut lines.

- Trim lines indicate the location of the final cut.

- Text and logos are kept away from creases and edges in safety zones.

Small changes are common during die-cutting and fast-speed printing. Your finished box will still look perfect since bleed and trim make up for such movement.

CMYK & Color Accuracy Inside Dielines

Every piece of packaging art that corresponds to a dieline needs to be created in the CMYK color model rather than RGB. What is the reason? Because printers do not use screen light, they use cyan, magenta, yellow, and black inks.

For printers to be reliable and consistent throughout the production process, die lines are needed. They produce a neat, polished appearance by guaranteeing the colors flow smoothly over folds, avoiding undesired color breaks along edges, and preserving visual uniformity across all panels.

Read More: Embossing VS Debossing: Make Your Packaging POP

Packaging Software Used for Dielines

Guesswork tools do not draw professional dielines. Specialized packaging software, like Adobe Illustrator and ArtiosCAD, is used to make them.

- Adobe Illustrator

- ArtiosCAD

- Esko Studio

- Impact CAD

Before anything is put into production, these tools let designers set scales, provide realistic 3D previews, and digitally test folds. They eliminate uncertainty at every level by exporting files that are ready for manufacturing. As a result, the team communicates more easily, makes fewer mistakes, and ensures satisfactory results while saving time and materials.

Die-Cutting: Turning Flat Into Functional

Die-cutting is where packaging design leaves the screen. A flat, printed sheet is physically modified into a useful, neat box that can be constructed, folded, and utilized on a large scale.

A specially designed metal die, fully guided by the dieline, presses into the material with measured force to cut customized shapes, create crisp edges, and build the supporting elements necessary for a package to function flawlessly.

A correctly set-up dieline guarantees that the die-cutting equipment operates reliably over hundreds or even thousands of units, creating boxes that are identical in terms of appearance, feel, and functionality. In addition to being aesthetically pleasing, uniformity has an immediate bearing on customer satisfaction, transit safety, and stacking strength.

Die-cutting is used to carve windows to highlight products, shape handles for convenient handling, and design tabs, slots, and locking mechanisms to keep the box intact. Because even a millimeter of misalignment can cause assembly problems or damage the buildup, every cut has to exactly match the printed artwork and folding lines.

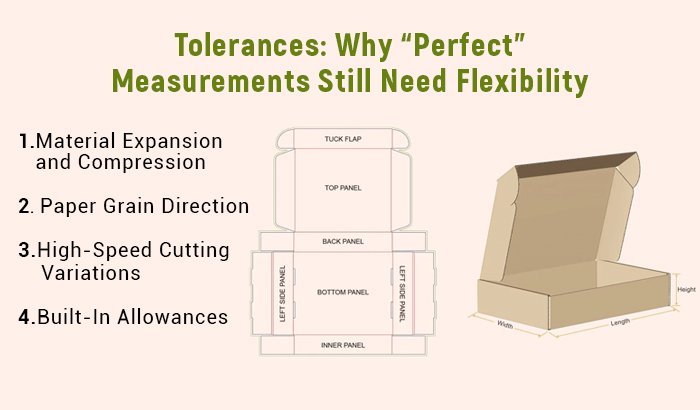

Tolerances: Why “Perfect” Measurements Still Need Flexibility

During real-world production, even the most carefully planned dieline may encounter minor deviations. Tolerances are a built-in buffer that guarantees your package functions brilliantly even in situations when materials and machines aren't fully predictable.

1. Material Expansion and Compression

Because they are not inflexible, paper and cardboard can gently expand or contract in response to temperature, humidity, and coating. These variations are taken into account by tolerances, which stop boxes from warping or folds from misaligning.

2. Paper Grain Direction

The way your cloth folds and creases depends on its grain. Ignoring it may result in unbalanced panels or damaged edges. Tolerances aid in modifying folds to conform to the material's inherent behavior.

3. High-Speed Cutting Variations

Quick manufacturing runs may cause small changes. Even at scale, cuts, folds, and bonded regions stay aligned thanks to small dieline adjustments.

4. Built-In Allowances

Subtle buffers surrounding cut, fold, and glue areas are part of a good dieline. Even though these tolerances are only a few millimeters, they might be the difference between a nicely assembled box and one that irritates production crews.

Dieline vs Packaging Design: Not the Same Thing

Packaging design is the creative component that determines first perception and attitudes towards the brand. This includes the following:

- Colors

- Typography

- Visuals

- Branding

- Emotional attraction.

Dielines, on the contrary, serve as the template, ensuring accuracy as well as uniformity throughout production. Dielines emphasizes:

- Structure

- Dimensions

- Cut/fold lines

- Glue sections

- Print safety zones

Packaging design entices consumers to buy your goods, whilst dielines guarantee it is easy to open, organize, store, pack, and repurpose. They work together but are not interchangeable.

Understanding Box Structures Through Dielines

Every box starts flat! Each box is three-dimensional! The magic takes place in the middle of it, which is when box structures come into existence.

Dielines determine packaging's structural DNA, which consists of:

- STE (Straight tuck end) boxes

- RTE (Reverse tuck end) boxes

- Auto-lock bottom boxes

- Sleeve boxes

- Mailer boxes

- Rigid boxes

- Display packaging

Every single structure is designed with a certain function in mind. Tuck-end boxes, for example, are meant for fast assembly and tidy presentation, whereas auto lock bottom boxes are built to accommodate bulkier products without sacrificing integrity. Sleeve boxes depend on friction and clean folds to keep their higher-quality appearance, whereas rigid boxes capitalize on exact panel proportions and strengthened edges.

What distinguishes dielines is how they take stress areas, folding patterns, and locking systems before manufacturing begins. Expertly made dielines promise:

- Weight is spread evenly among the panels.

- Folding lines facilitate flawless assembly.

- The corners always stay crisp and symmetrical.

- Structural integrity is protected while shipping and storing.

Along with aesthetics, construction has a direct impact on usefulness and durability. A well-engineered dieline maximizes material consumption, minimizes instances of failure, and refines every aspect of the unboxing experience.

Packaging Materials: Dielines Adapt to Everything

A good dieline takes into account how different materials react. Cardboard, kraft, corrugated, rigid chipboard, and environmentally friendly recycled materials are examples of standard packaging materials. Each material has its own:

- Thickness

- Flexibility

- Fold tolerance

- Weight limits

Rigid material cannot be used with a dieline made for thin cardboard, and vice versa. Strength, folding precision, and visual interest all require adjustments.

What Happens When a Dieline Goes Wrong?

A simple packaging job can become an expensive pain if there is even the slightest error in a dieline that affects the entire production process. What could go wrong is as follows:

1. Costly Retooling of Dies

Metal dies and cutting tools may need to be adjusted or replaced entirely if your dieline is imperfect. This may result in unforeseen expenses and manufacturing schedule delays.

2. Delays in Production

Your production line may come to a complete stop due to improper folds, faulty glue locations, or inaccurate cut lines. Workflow is slowed down, and delivery schedules are impacted when even little errors necessitate manual intervention.

3. Wasted Print Runs

Several batches of printed sheets become unusable due to a faulty dieline. Such mistakes consume resources, time, and money.

4. Product Damage During Shipping

Weak structural integrity caused by incorrect folding, glue placement, or panel thickness can lead to boxes collapsing or tearing during shipping, putting your products at risk.

5. Retail Rejection

Boxes may collapse or tear during shipment due to weakened structural integrity brought on by mistaken folding, adhesive application, or panel thickness, jeopardizing your products.

Final Remarks

The invisible power behind packaging that functions, endures, and makes an impression is called Dielines. They blend creativity and usefulness via everything from durability and structure to designing precision and production efficiency. Understanding dielines results in fewer mistakes, more efficient use of materials, more seamless scaling, and packaging that functions as well as it looks.

Ready to Turn Smart Dielines Into Stunning Packaging? Packaging is designed to function at We Print Your Box. Our knowledgeable staff develops exact dielines based on your product, content, and brand objectives. We manage everything with no guesswork, from structure to print accuracy.

We can help with bulk manufacturing, retail packaging, and custom boxes. Contact us right now, and together we can create packaging that truly delivers.

Recent Posts:

13 Foil Stamping Colour Trends: Gold, Silver, Holographic & More

Packaging is now more than simply a cover for your goods; it's the world's first glimpse of your bra...

Embossing VS Debossing: Make Your Packaging POP!

The nuances are crucial when it comes to personalized packaging. While intriguing fonts and colorful...

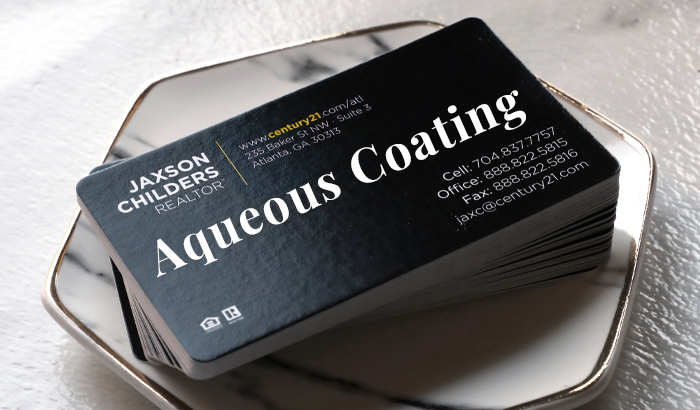

Aqueous Coating: The Unsung Hero That Makes Your Prints Look (and Feel) Expensive

Excellent printing involves more than just bright colors and intriguing illustrations. It has to do...